Table of Contents

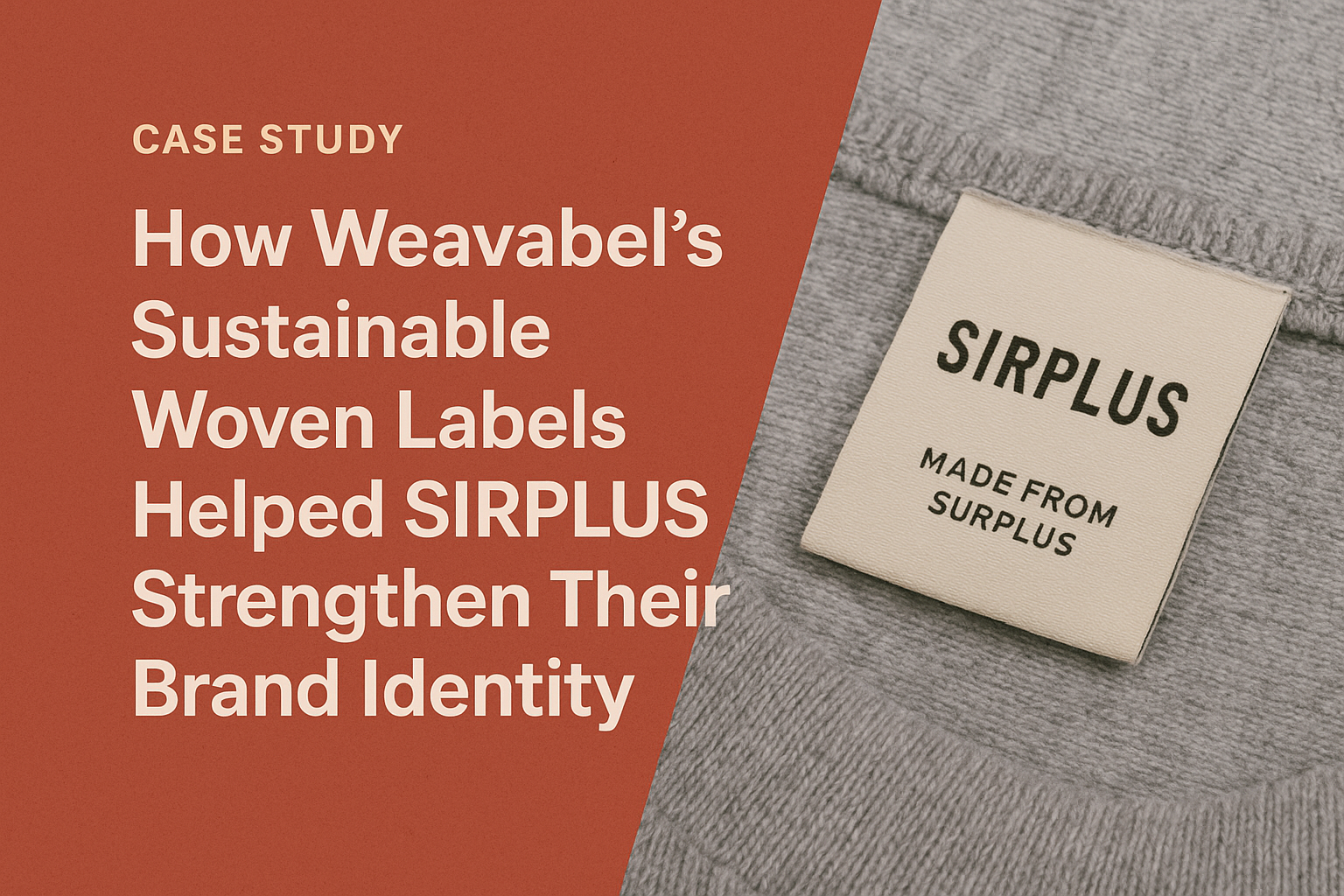

In today’s fiercely competitive fashion and textile market, brand identity is defined not just by innovative designs and effective marketing, but critically, by the finishing details on the product. One of the most durable and consistent branding tools available is the woven label. A high-quality custom woven label immediately communicates professionalism, quality, heritage, and trust, establishing a lasting memory long after the customer has left the retail environment.

SIRPLUS: Reducing Waste, Defining Quality

Founded by Henry Hales, SIRPLUS is built on the principle of reducing textile waste. The brand began by utilizing surplus, high-quality fabric to create premium, sustainable menswear. Their ethos is centered on the circular fashion model, utilizing materials such as recycled polyester, silk, linen, and cashmere.

Weavabel: Expertise in Sustainable Labelling

Weavabel, headquartered in Yorkshire, UK, operates as a global supplier of garment branding trims and sustainable packaging. They lead with an eco-first approach, focusing on materials like recycled yarns, FSC-certified swing tags, and compostable packaging.

The Challenge: Aligning Every Stitch with Sustainability

SIRPLUS faced a crucial challenge: how to ensure every single element of their high-quality garments—including the internal trims—aligned with their sustainable mission.

-

The Conflict: Conventional garment labels frequently use virgin polyester or non-recycled synthetics, which would directly contradict SIRPLUS’s core sustainability narrative.

-

The Need for Consistency: They required a reliable, quality partner who could consistently deliver complex, eco-friendly trims across multiple manufacturing sites in both Portugal and the UK.

The Solution: A Complete Sustainable Woven Label Package

Weavabel collaborated directly with SIRPLUS to develop a comprehensive set of trims that upheld their environmental commitments without sacrificing luxury feel. The solution was an integrated package of sustainable woven labels and accessories:

-

100% Recycled Polyester Woven Labels: Used for the main brand name and essential care labels. This commitment ensures the primary brand touchpoint aligns with the recycled fabric sourcing.

-

Recycled Polyester Satin Care Labels: Selected specifically to maintain a soft, premium feel against the skin, proving that eco-friendly garment trims can also be high-quality.

-

Printed Cotton Labels: Used for additional branding and product information where flexibility was needed.

-

Bamboo Paper Swing Tags: Replaced conventional hang tags with a regenerative, environmentally superior material.

Weavabel streamlined the supply chain by shipping these complete trim packages directly to SIRPLUS’s manufacturing facilities in the UK and Portugal, ensuring seamless integration into the production schedule.

Results and Strategic Impact

The partnership delivered tangible results, strengthening SIRPLUS’s brand identity and operational performance:

1. Authentic Brand Alignment

By integrating 100% recycled woven labels and sustainable swing tags, SIRPLUS reinforced its core value of waste reduction. These labels are not merely functional; they are a clear, physical expression of the brand’s commitment to circular fashion.

2. Enhanced Customer Perception

In the premium menswear market, sustainability is a deciding factor. The use of these eco-conscious woven labels strongly positioned SIRPLUS in the ethical fashion space. The label effectively functions as a “micro-story,” visibly communicating the brand’s commitment to responsible sourcing and manufacturing.

3. Supply Chain Consistency

Weavabel’s global logistics capability ensured the exact same high quality of trim was delivered consistently to all of SIRPLUS’s manufacturing sites. This consistency is vital for maintaining a unified and recognizable brand presence across all garments, regardless of their origin.

4. Operational Smoothness

Weavabel’s efficient turnaround times (noted to be typically 2–4 weeks) reduced the risk of label-related production delays, allowing SIRPLUS to maintain its manufacturing schedules and focus on product quality.

Key Learnings for Fashion Brands (Especially UK-Based)

The SIRPLUS and Weavabel case study offers a valuable blueprint for brands seeking to embed their values into their products:

-

Make Your Label a Storyteller: Your woven labels should actively reinforce your brand story. They are essential brand touchpoints, not just regulatory tags.

-

Insist on Sustainable Materials: Choosing recycled yarns, bamboo paper, or organic cotton labels directly aligns your trims with your overarching sustainability goals.

-

Prioritize Quality & Compliance: Partnering with an experienced supplier ensures quality, colour fastness (e.g., testing to standards like BS 5742), and reliable global compliance.

-

Standardize Sourcing Globally: If you manufacture internationally, standardizing your sustainable woven label sourcing maintains brand consistency and quality across all geographies.